With disposable gloves in high demand, vinyl is proving its worth beyond food service and janitorial applications.

The disposable glove marketplace continues to suffer from chronic supply shortages. Because of COVID-19—as well as factors from labor and capacity issues to a lack of raw materials—nitrile and latex gloves are especially difficult to come by. Prices are high and only going higher.

Vinyl gloves, however, are proving a dependable alternative. Not only are they more affordable than other materials, but they are also simply more available. And they are better made than ever before.

The second generation of disposable gloves after natural rubber latex, vinyl began to gain acceptance in the 1990s. Increased awareness of HIV in the 1980s had fueled wider adoption of disposable gloves across the healthcare industry. Backlash against both the cost and the allergy issues surrounding latex, however, helped vinyl carve out its spot in the marketplace.

A material of many uses

Vinyl gloves are made from polyvinyl chloride (PVC), used in countless products from pipes to credit cards to toys to food packaging to medical devices. Normally rigid, it is mixed with a plasticizer to make the material flexible and soft for molding into gloves. Vinyl gloves consist of only PVC monomers, making them more cost-effective than nitrile, which is made from another synthetic material, nitrile butadiene rubber (NBR).

The processes for creating nitrile and vinyl are similar. The NBR used for nitrile gloves is a copolymer, a substance derived through the bonding of different molecules. In the case of NBR, the two parts are butadiene and acrylonitrile, which chemists combine using a process known as co-polymerization. These molecules provide specific advantages for the gloves: Acrylonitrile enhances the chemical resistance, while butadiene creates flexibility and tear resistance.

A long-evolving process

Scientists accidentally discovered vinyl through experiments during the 19th century. German inventor Friedrich Heinrich August Klatte first patented the material in 1913, when he found a way to use sunlight to polymerize vinyl chloride. Researchers have since determined which additives to include to make the material more flexible.

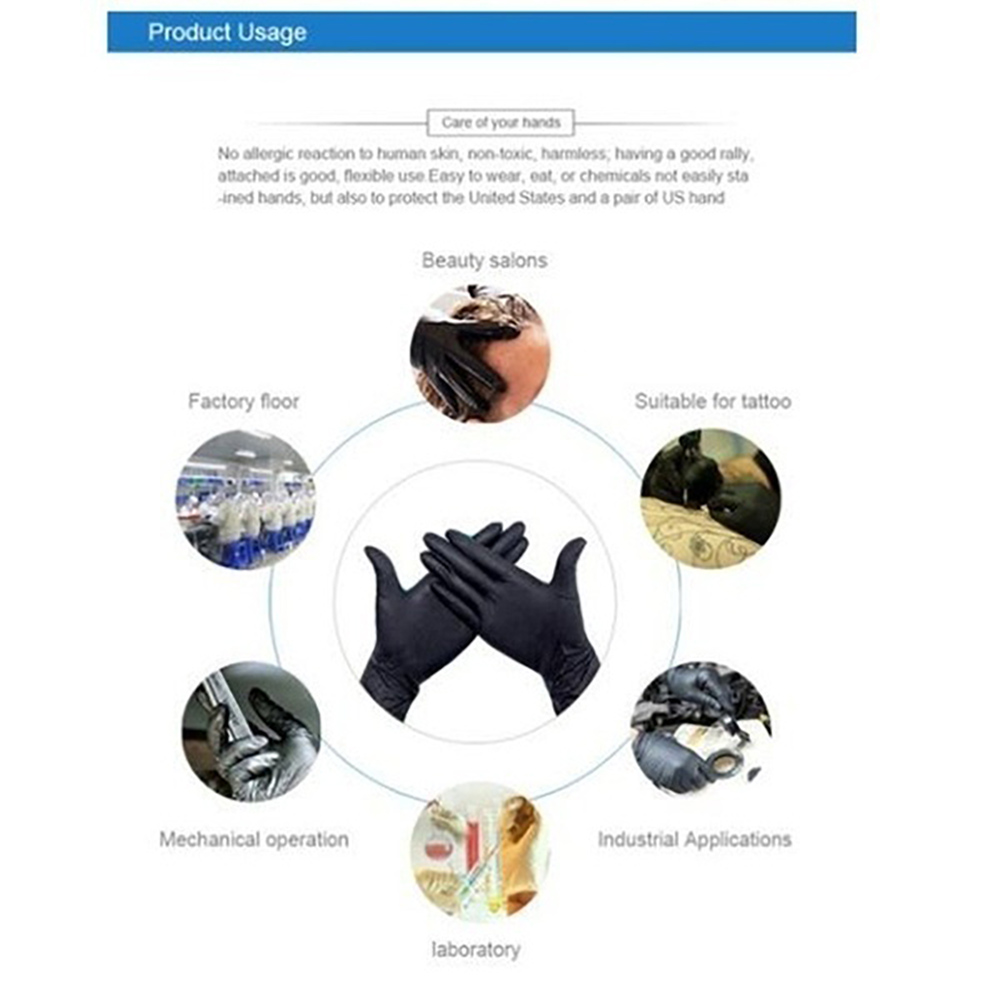

Vinyl gloves come in both industrial and exam grades, both powdered and powder free. They have a comfortable fit that is looser than latex or nitrile. Vinyl eliminates concerns about latex allergies.

It is popular for applications where frequent glove changes are required, including food service, beauty & salon, and janitorial. In food service, the No. 1 priority is preventing the spread of foodborne illness, something that vinyl gloves—along with frequent handwashing and changing gloves between tasks—are particularly adept at.

A dependable all-around choice

Vinyl also delivers dependable barrier protection against most cleaning solutions and solvents, including hydrofluoric acid, nitrilotriacetate, and phosphoric acid. In exam grade, it guards healthcare workers against bloodborne pathogens and on-the-job transmission of germs.

Vinyl gloves may not have the cachet that nitrile gloves have achieved in their relatively short time on the market. But in these times of COVID-19, vinyl may be the best option for numerous applications.

During the current glove shortage, hybrid vinyl gloves are seeing more interest. They combine PVC with elastomers to increase stretch, improve fit, and provide better barrier protection.

Even if vinyl isn’t the future, it certainly is the present. Give it a try: You might be surprised at how well it suits your customers’ needs.